Eco-friendly alternatives for cotton

Cotton is the king of natural fibres, but its large water footprint can create problems in areas where it’s grown. Can fibres from banana stem better alternatives?

India is one of the world’s largest cotton producers and exporters. However, the Cotton Association of India has been in a bit of a bind this year. It has already had to lower its cotton yield estimate for the 2018-2019 season three times, always because of lack of water. Drought-like conditions in parts of India have even forced farmers to uproot their crops to preserve what little moisture remains in the soil.

“The water consumed to grow India’s cotton exports in 2013 would be enough to supply 85% of the country’s 1.24 billion people with 100 liters of water every day for a year. Meanwhile, more than 100 million people in India do not have access to safe water,” states an article in The Guardian newspaper

From cotton to leather, the creation of fashion’s raw materials consumes vast amounts of resources and generates huge amounts of pollution and emissions. There are man-made fibres, such as polyester, which are derived from fossil fuels, and around 20% of the world’s wastewater comes from the fashion industry. It also produces huge amounts of microfibres, which eventually find their way into the ocean.

It’s no surprise there is a growing call for more ethically and environmentally responsible clothing. Bananas are getting in on the act. While the fruit is easy to offload at the market, the pseudostems are a waste product that need to be disposed of.

Musa fibre is a durable material made from the stem of the banana tree – it’s also known as banana fibre. Biodegradable, very strong yet capable of being spun and woven, musa fibre is already in use as an alternative to traditional textiles. It is comprised of cellulose, hemicelluloses and lignin, and bonded using natural gums. It has been used in Japan for centuries. Banana fiber is known as the most endurable fiber and even evalued better than silk in quality. In the future, fabric made from banana fiber is expected to be an alternative fiber for cotton and silk.

Slowing down Fast Fashion

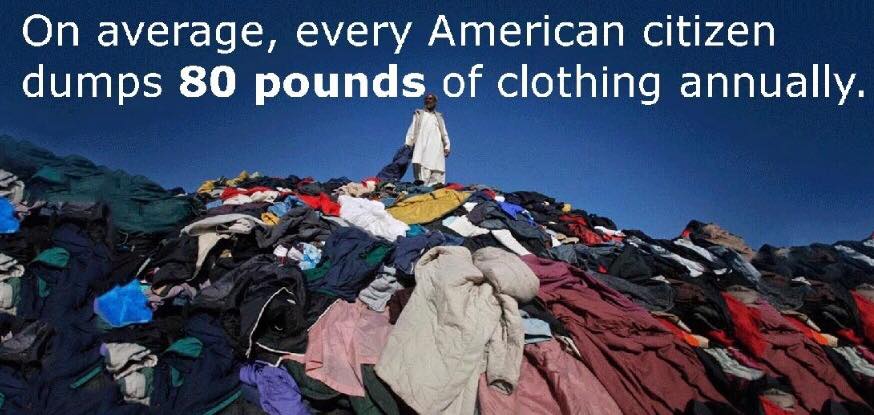

With exponentially growing populations and fashion trends coming and going faster than ever, we are beginning to realize the effects of our industrial explosion from the past 100 years. Fashion is now the world’s second leading cause of pollution trailing only oil.

While cotton was gaining popularity as a cheap textile for centuries, banana fiber usage was all but forgotten. At the current scale of manufacturing, the unnatural process used to make clothing from cotton is causing landfills to overflow.

After being treated with chemicals, the cotton no longer continues to decompose as it would naturally. In many places around the world, leather manufacturing also continues to poison environments and the humans that work in the factories. This remains true for many massively produced textiles in modern society.

Environmental champions have shown that sustainable manufacturing practices and processes can help reduce the negative impacts of global consumerism. This now serves as a demand driver for products and companies that leave a smaller carbon footprint.

Socially aware consumers are getting behind social impact companies like never before. For centuries there has been an overwhelming supply of banana fiber material ready for handmade paper making, and now the demand is rising.

Modern Uses

The uses for banana fiber have not so much changed over time, but the processing has evolved and improved enough to make it commercially desirable. The fibers can be made into cloth, mats, woven materials, and handmade papers.

With the improvements in extraction and turning the fiber into a pulp, handmade paper stands out as one of the biggest opportunities for banana fiber. The thickness of the paper can be adjusted to achieve the desired texture and to make it suitable for a finished product.

Thick papers can be made to achieve a card stock feeling that is suitable for business cards and greeting cards or thin enough for tissue paper. Papermaking artisans have also experimented with mixing various fibers including recycled paper pulp, pineapple and sakau to achieve a wide variety of papers.

Source: https://www.swissinfo.ch/eng/exotic-fibres_why-bananas-could-be-the-fabric-of-the-future/44815992

https://www.weforum.org/agenda/2019/04/the-clothes-of-the-future-could-be-made-from-pineapples-and-bananas/

https://greenbananapaper.com/blogs/about-us/banana-fiber-paper

You may also be interested in

Musa Pacta participates in launching project VIE/039 in Thua Thien – Hue with a budget of 2 million Euros funded by the Government of Luxembourg and the Government of Vietnam

The People’s Committee of Thua Thien – Hue province and the Luxembourg Development Cooperation Agency...

Dec

VIETNAM BANANA FIBER CRAFTS – MUSA PACTA

Banana fiber is a unique natural handmade material, made from the inner fiber of the...

Apr

PLAN TO GROW MUSHROOMS ON FRESH BANANA GROUNDS

PREPARING MUSHROOM GROWING SUPPLIES 1.Prepare the mushroom growing house Area: about 100m2, corrugated iron roof,...

Jul

Big dreams for the banana industry

Though prices fluctuate all the time, in general they are on the rise, from $300...

Jul

Banana fiber: a green industry that is saving the environment

A fabric made out from banana fiber could well be next green apparel of the...

Jul

Banana fiber: a revolution in textile

Banana plant (scientific name: Musa acuminate) not only gives delicious fruits but also provides textile fiber,...

Jul

Banana fiber applications

The stem of the banana plant is usually thrown away once the plantain is harvested....

Jul

BANANA FIBER BLENDED WITH COTTON

A New Natural Fiber that offers an alternative to Linen Cotton, Linen & Silk are...

Jul